Precautions for Using Shell-and-Tube Coolers

Important Notice: Internal freezing of the cooling medium may cause damage to the cooler!

1. Use purified water as the cooling medium during operation!

2. When storing or using the unit in environments below 5°C (41°F), add antifreeze to the water!

3. Drain all water from the system when decommissioning or leaving it idle to prevent freezing damage to the cooler!

Maintenance of Shell-and-Tube Coolers

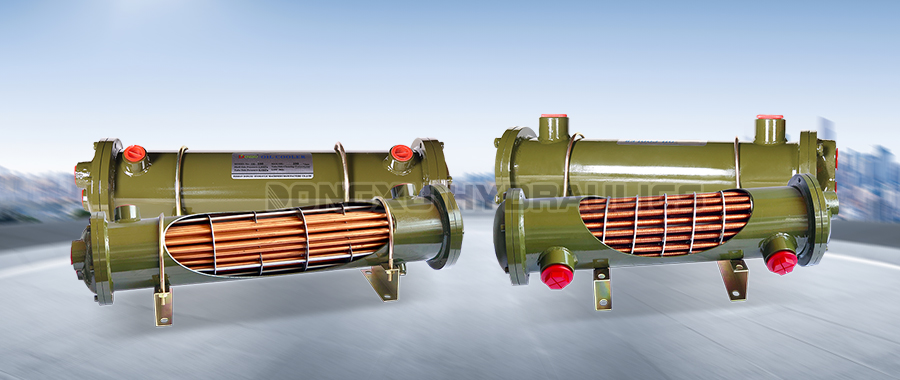

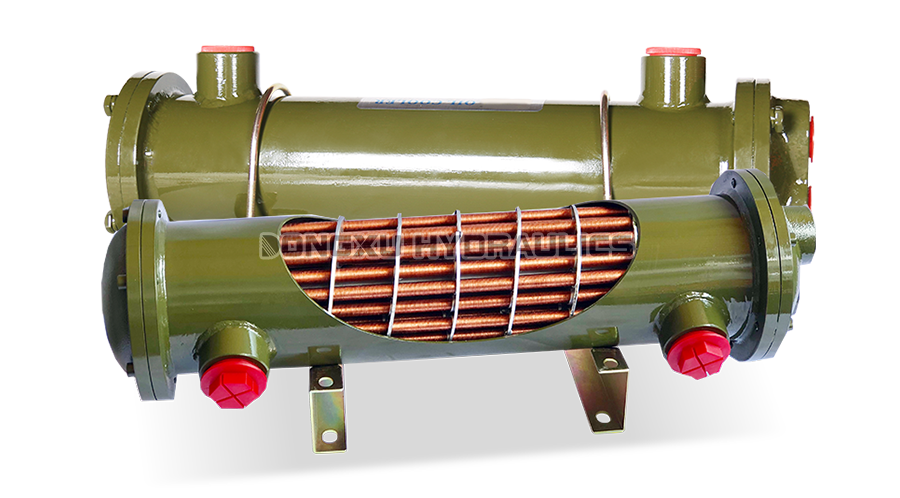

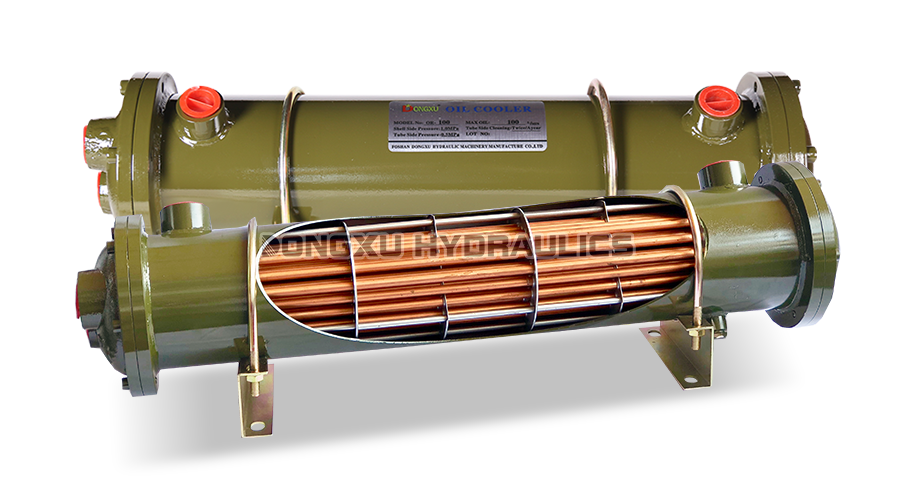

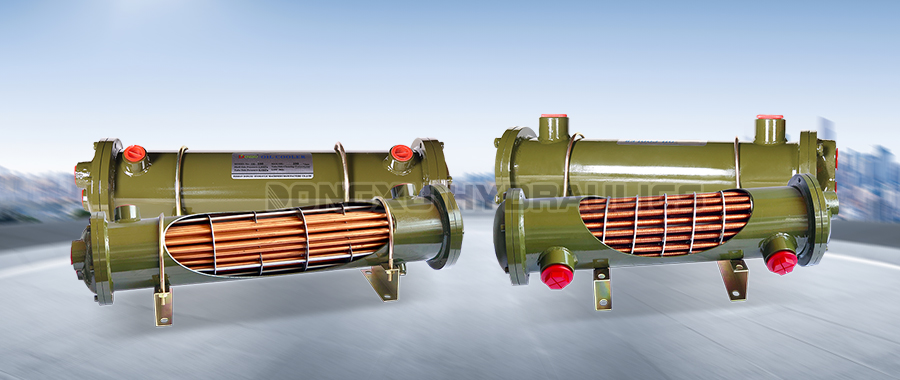

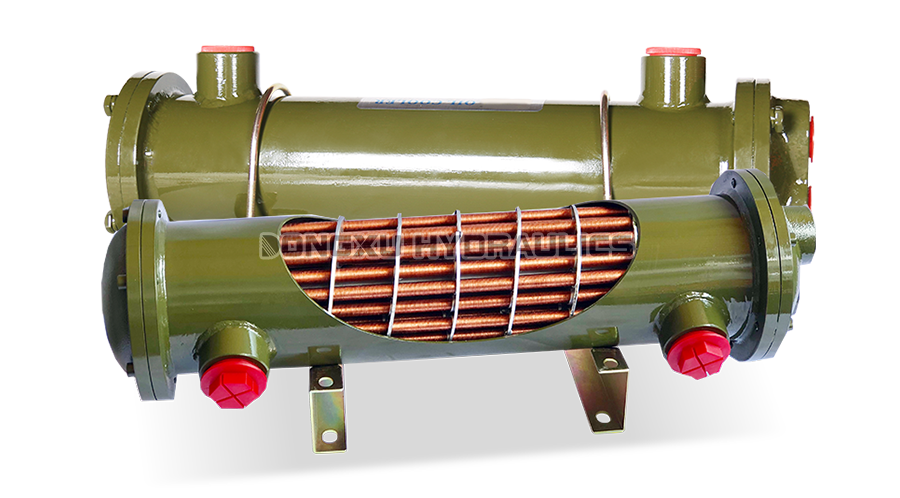

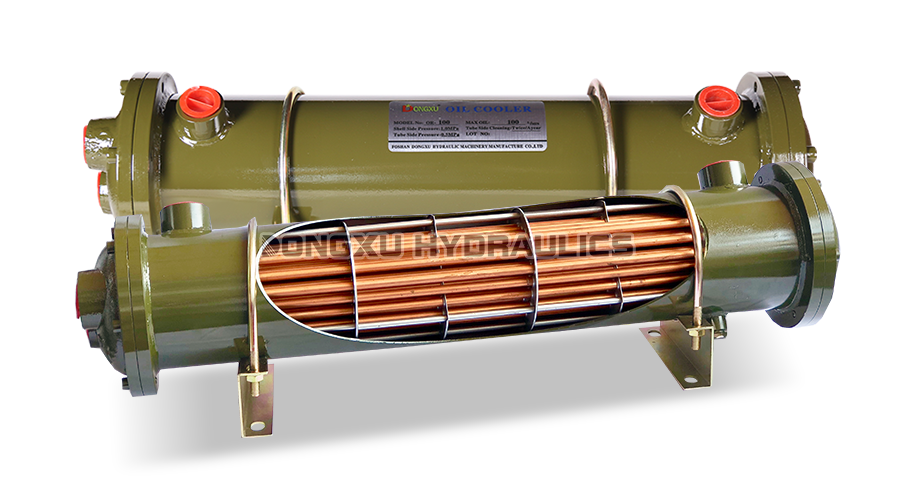

● A shell-and-tube cooler is a device placed within a cooling water circuit that utilizes the temperature of the cooling water to regulate the temperature of lubricating oil.

● Its heat transfer tubes are made of copper tubing rolled with cooling fins, enabling heat exchange between two liquid media with a certain temperature difference. This achieves the purpose of lowering oil temperature and ensuring normal equipment operation.

● After prolonged operation, scale buildup on the cooler tubes increases thermal and flow resistance, gradually degrading heat exchange performance until it fails to meet operational requirements.

Clearly, maintenance should focus on scale removal. Several cleaning methods are introduced for reference:

Method 1: Electric Pipe Cleaning Tool

This method employs an electric pipe cleaning tool, where a motor drives a flexible shaft to rotate. The shaft end is fitted with a nylon or steel wire brush for rotational scrubbing. Water is injected around the shaft through a watertight cover to promptly wash away loosened scale.

Method 2: Manual Rotating Wire Brush Cleaning

A round tube is used with a wire brush welded at one end, matching the pipe's inner diameter. The brush is rotated while being advanced through the pipe. Dirt accumulates inside the tube cavity, preventing it from building up and making advancement more difficult. This method is commonly used but involves high labor intensity.

Method 3: High-Pressure Water Flushing

Employ a high-pressure pump (10–20 MPa) to spray water for flushing. This method yields good results and is primarily used for inter-tube cleaning.

Method 4: Automatic Sponge Ball Cleaning

Sponge balls are used for automatic cleaning inside heat exchange tubes. Different hardness levels of sponge balls are selected based on the scale layer. For particularly hard deposits, sponge balls with a “band” of emery can be employed. The process involves introducing relatively soft and elastic sponge balls into the heat exchange tubes. As the sponge balls compress, they make contact with the inner wall of the tube. The relative movement between the ball and the tube wall continuously rubs against the surface, removing deposits.

Method 5: Regular Water Replacement + Air Gun Blasting

Frequently replace cooling water, as usage generates scale, oil residue, and rust deposits—common causes of copper tube blockage. Remove front and rear covers, then use an air gun to blast each copper tube opening, expelling accumulated debris. Reinstall covers and replace any damaged O-rings.

Maintenance of Shell-and-Tube Coolers

● Most cooler failures are caused by issues with the cooler tubes.

● Tube wall thinning and perforation occur due to corrosion, cavitation, and wear. Additionally, thermal expansion and contraction, along with vibrations generated by fluid movement, can cause damage at connections and other points. Once a cooler tube is damaged, the two media will intermix. Prompt repair is essential. The following methods are provided for reference:

Method 1: Tube Plug Sealing

Locate the damaged cooling tube and seal both ends with tube plugs. The plug taper should be 3–5 degrees, and the plug material hardness must be equal to or less than the tube hardness. The total number of sealed tubes must not exceed 10% of the total.

Method 2: Tube Replacement with Expansion Jointing

Remove the damaged tube and replace it with a new tube, then re-expand the joint.

Method 3: Rebuilding/Tube Bundle Replacement

For leaks at tube-to-tube sheet connections, rebuild the joints. If severe corrosion is present, replace the entire tube bundle.

GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8