In industrial production, the cooling efficiency of oil chillers directly impacts equipment stability, lifespan, and energy consumption. Selecting the right cooling method is key to maximizing performance. Many wonder: What distinguishes the two cooling methods for oil chillers? How should one choose?

Today, we break down the two mainstream cooling methods—air-cooled and water-cooled—comparing them in detail from principles, installation, performance, to applicable scenarios. This will help you quickly identify the optimal solution.

I. Core Difference: Air-Cooled or Water-Cooled Heat Dissipation?

Oil-cooled machines rely on refrigerant circulation to dissipate heat from the oil. The fundamental distinction in heat dissipation lies in the refrigerant's cooling method—whether it employs air cooling or water cooling. This seemingly simple difference determines the equipment's installation complexity, operational costs, and suitable environments.

II. Air-Cooled Oil Chillers: Flexibility and Convenience as Core Advantages

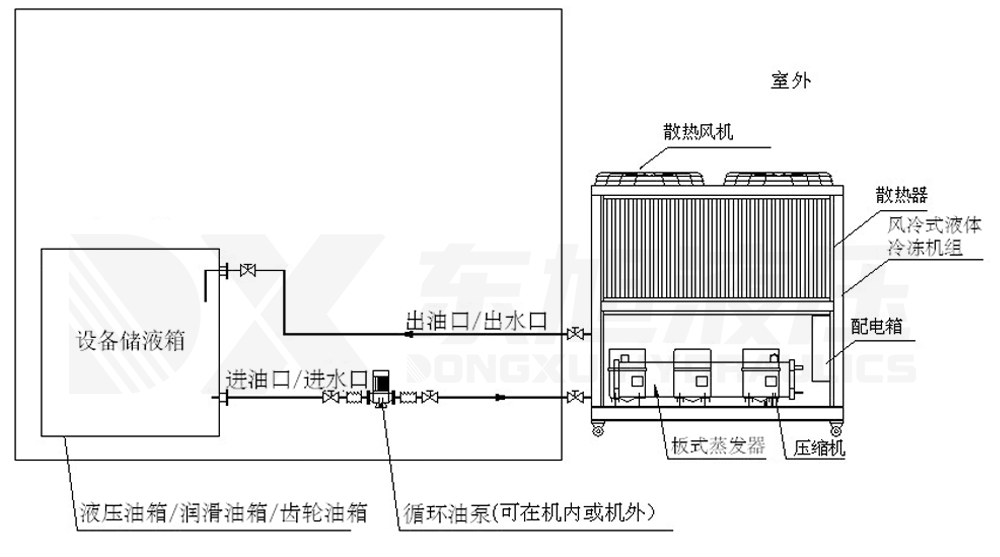

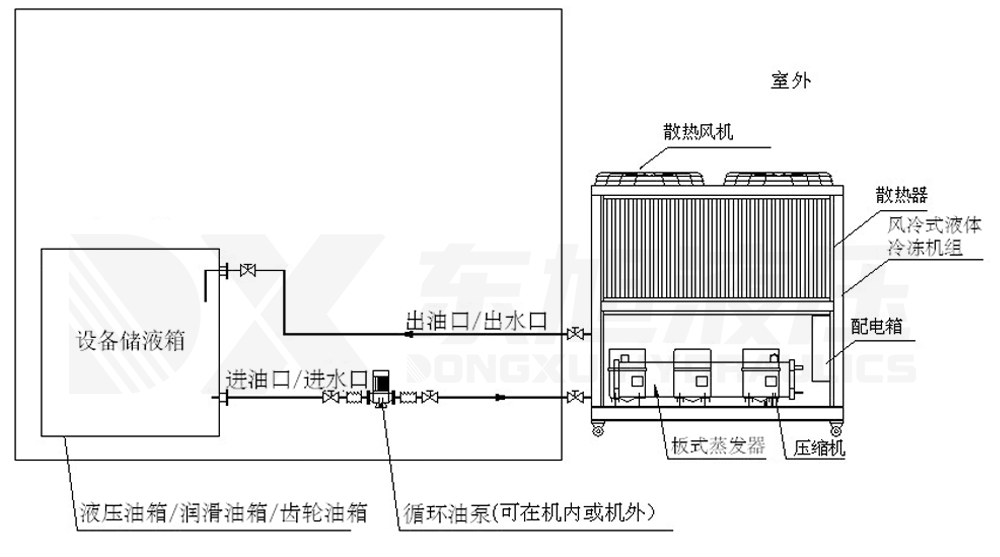

Air-cooled oil chillers utilize finned condensers with built-in fans for forced ventilation, directly dissipating refrigerant heat without requiring external auxiliary equipment.

1. Core Advantages: Simple Installation and High Flexibility

• No Additional Accessories: Eliminates the need for cooling towers, cooling water pumps, and piping. Ready for rapid deployment upon unboxing, reducing installation costs and time.

• Portable Design: Ideal for small-to-medium applications with modest cooling demands (e.g., compact machine tools, laser equipment). Compact size allows relocation alongside equipment.

• Minimal Site Requirements: Operates with power supply + basic ventilation, accommodating flexible workshop layouts without fixed cooling systems.

2. Critical Considerations: Ambient Temperature

• Requires Adequate Ventilation: Enclosed spaces cause heat buildup, reducing cooling efficiency and potentially causing overloads.

• Ambient Temperature ≤43°C: Beyond this threshold, the “hot air” expelled by fans fails to meet cooling demands, causing a sharp drop in cooling capacity.

GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8