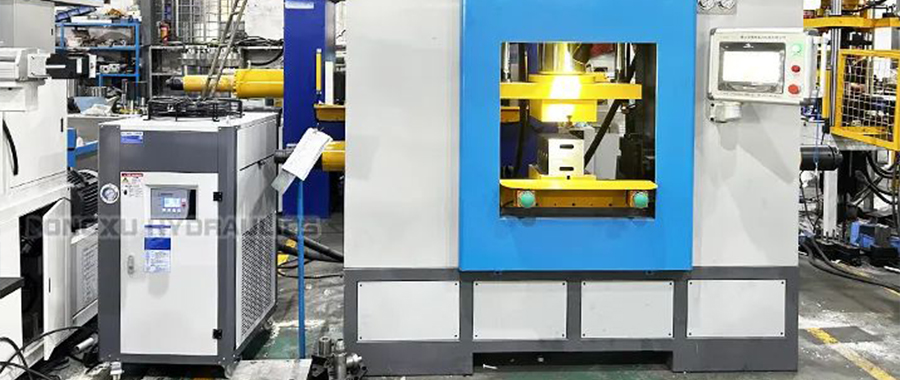

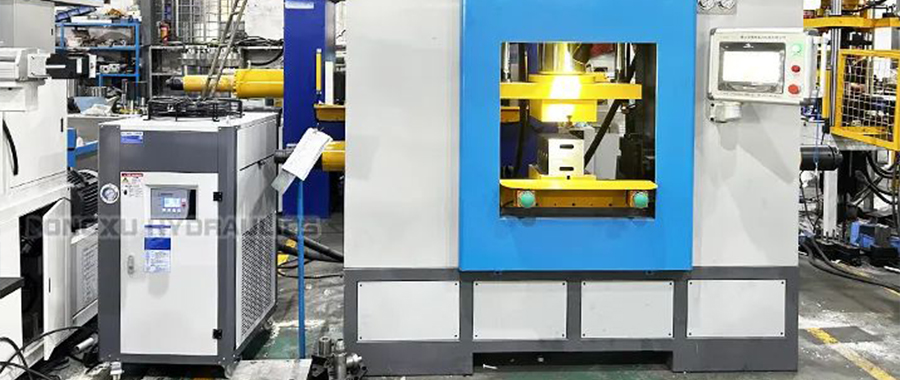

Generally speaking, the oil cooler adopts two kinds of circulating cooling methods: built-in oil pump circulating cooling method and external oil pump circulating cooling method.

Built-in oil pump circulating cooling method means that the oil pump inside the oil cooler will pump out the oil in the oil tank and send it into the heat exchanger of the oil cooler through the oil pipeline to exchange heat to achieve the purpose of cooling down, and the cooled down oil will return to the oil tank to be mixed and then pumped out to re-circulate. (The built-in oil pump of the oil cooler is suitable for short distance pipeline installation, generally the best distance is ≤5 metres.)

External oil pump cooling method means that the oil cooler is not equipped with oil pump inside, and the oil is pumped into the heat exchange system of the oil cooler through the external independent oil pump for heat exchange to achieve the purpose of cooling. (The external oil pump of the oil cooler is suitable for long-distance pipeline installation.)

Translated with DeepL.com (free version)

These two circulating cooling methods have their own characteristics, the user's actual installation distance to choose the built-in or external oil pump.

GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8