Accumulators can not be ignored before the installation of the inspection.

Then we should be before the installation of the accumulator to carry out those checks?

Whether the accumulator is the same as the selected specifications, whether the filling valve is tight, whether there is any damage caused by transportation that affects the use and whether the oil inlet of the oil inlet valve is blocked.

Basic requirements for accumulator installation

The basic requirements for accumulator installation are as follows.

(1) Accumulator of the viscosity of the working medium and the use of temperature should be the same as the requirements of the working medium of the hydraulic system.

(2) Accumulator should be installed in the inspection, maintenance convenience.

(3) Used to absorb shock, pulsation, the accumulator should be close to the source of vibration, should be installed in the easy to occur at the impact.

(4) The installation position should be far away from the heat source, in order to prevent the system pressure from rising due to the thermal expansion of the gas.

(5) Fixing should be firm, but not allowed to be welded on the main unit, it should be firmly supported on the bracket or the wall. When the diameter to length ratio is too large, hoop reinforcement should also be provided.

(6) Sac accumulator in principle should be installed vertically with the oil mouth downward, tilted or horizontal installation, the skin bag due to buoyancy and shell unilateral contact, there is a danger of hindering the normal expansion and contraction of the operation, accelerate the damage to the skin bag, reduce the function of the accumulator.

Therefore, generally do not use tilt or horizontal installation method. For diaphragm-type accumulators without special installation requirements, can be installed vertically with the oil port down, tilt or horizontal installation.

(7) In the pump and the accumulator should be installed between the check valve, so as to avoid the pump stops working, the accumulator in the oil back into the pump flow back to the tank, accidents.

(8) In the accumulator and the system, should be installed between the shut-off valve, this valve for filling, adjustment, inspection, maintenance or long-term shutdown.

(9) Accumulator installed, should be filled with inert gas (such as: N2), is strictly prohibited to fill oxygen, hydrogen, compressed air or other flammable gases.

(10)When assembling, disassembling and handling, the gas must be released.

Airbag assembly

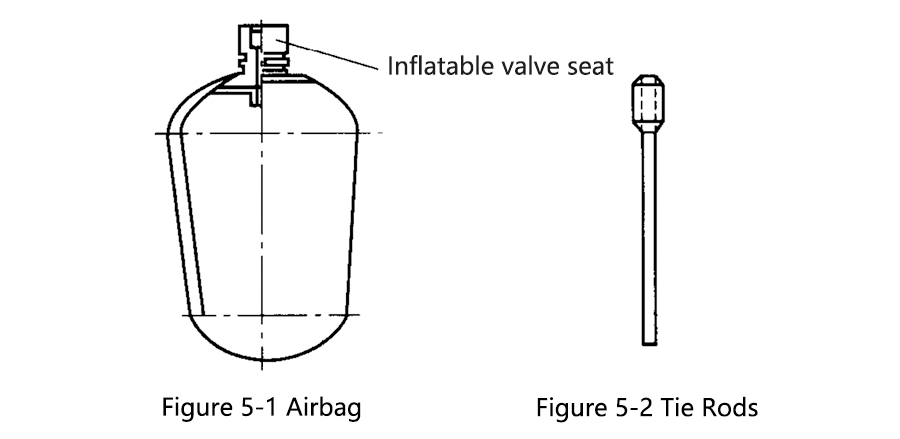

The structure of the airbag is shown in Figure 5-1. When inflated, the airbag first in its largest diameter, the thinnest thick upper expansion, and then the lower part of the gradual expansion of the airbag to push the airbag outward to the shell side walls, while the airbag filled with the entire container. The friction between the outer wall of the airbag and the dry inner wall of the shell is very large, and when inflated, the air race will make the deformation is not uniform, the local stretch is too large and rupture. Therefore, before assembly, a small amount of hydraulic oil should be poured into the shell, and the oil will be coated evenly on the inner wall of the shell, so that the inner wall of the shell and the outer wall of the airbag to form a layer of oil cushion between the deformation of the airbag, the airbag can be deformed, between the airbag and the shell to play a lubricating effect.

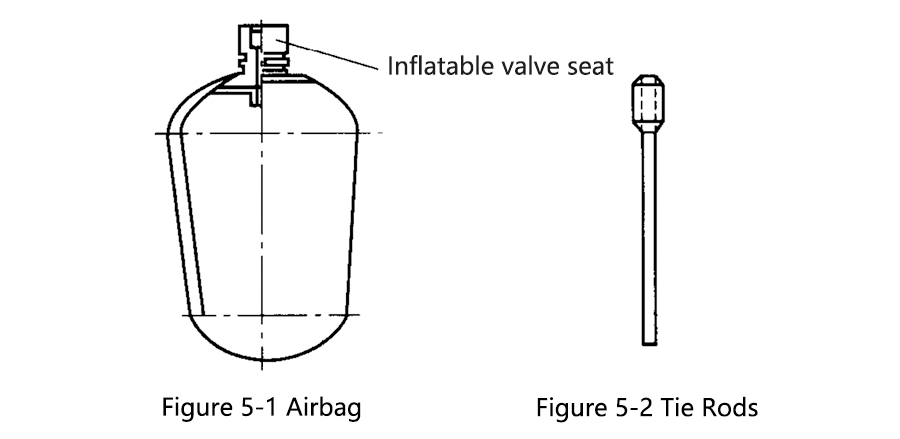

Before the assembly of the airbag, the same should be applied to the outer wall of the airbag with hydraulic oil, and the gas in the airbag will be drained and folded. At this point, the auxiliary tool pull rod (see Figure 5-2) can be screwed to the inflatable valve seat of the airbag, and then together with the shell through the shell at the lower end of the large openings into the shell, in the shell at the upper end of the pull rod, and then uninstalled the pull rod, install the round nut, so that the airbag is fixed on the shell.

GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8