Tube cooler use precautions

Warm reminder: internal media icing will cause damage to the cooler!

1.Please use purified water as cooling medium during operation!

2.Stored or used in ambient temperatures below 5 ℃, the water must add antifreeze!

3.Discharge all the internal water when it is out of use or idle to avoid icing damage to the cooler!

Maintenance of Tube Coolers

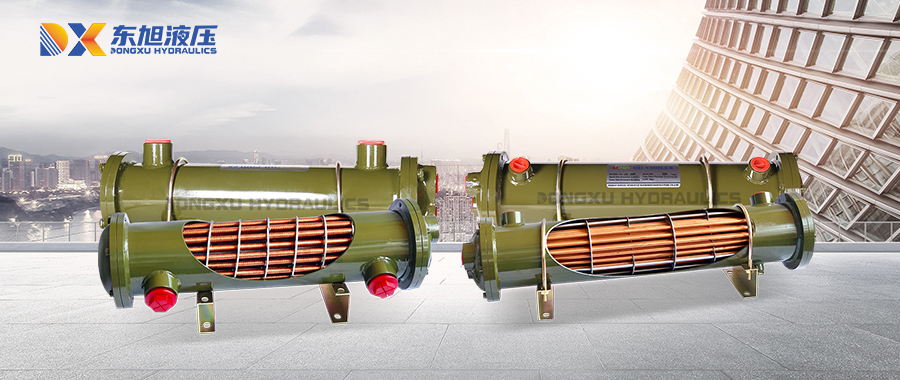

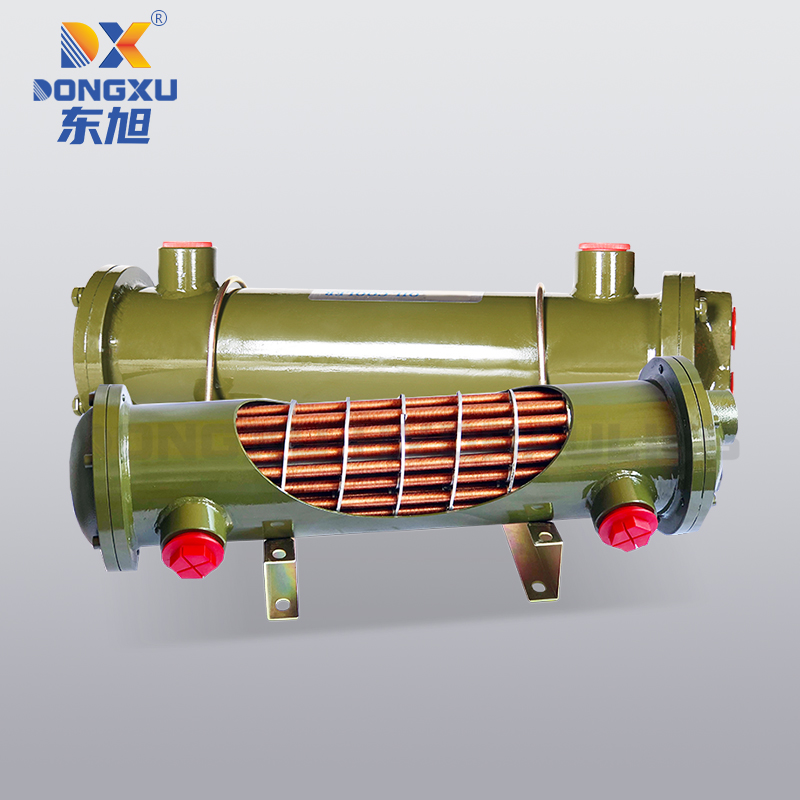

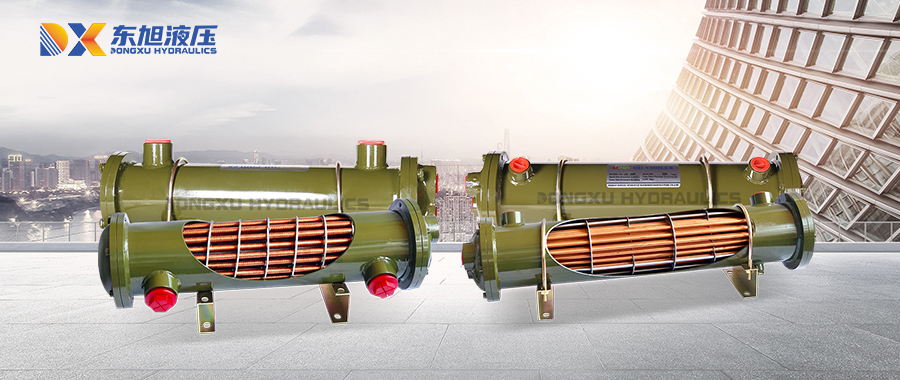

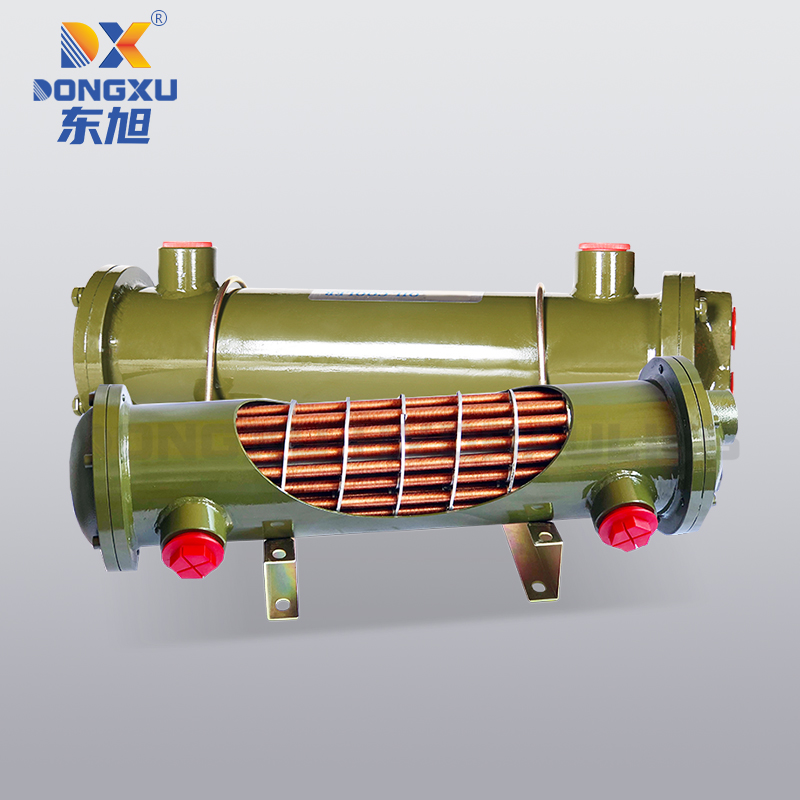

●The tube cooler is a device which is placed in the cooling water circuit and utilizes the temperature of the cooling water to control the temperature of the lubricating oil.

● Its heat transfer tube adopts purple copper tube rolled out with heat dissipation fins, which can make the two liquid mediums with a certain temperature difference realize heat exchange, so as to achieve the purpose of lowering the oil temperature and ensuring the normal operation of the equipment.

● Cooler long-term work, the cooler tube surface will accumulate scale and increase the thermal resistance and flow resistance, so that the heat transfer performance gradually reduced, so as not to ensure that the cooler requirements. Obviously, the focus of maintenance should be placed on the dirt cleaning, here are several cleaning methods for reference:

Method 1: The use of electric pipe cleaning tool, that is, driven by an electric motor for rotary movement of a flexible shaft, the end of the shaft set of nylon brush or steel wire brush for rotary scrubbing, and through a non-leakage cover to the water injected into the shaft around, in order to scrub out the loose dirt in a timely manner.

Method 2: With a round tube, one end of the welded and tube inner diameter similar to the wire brush while rotating while advancing, dirt can be deposited in the inner lumen of the tube, will not produce dirt thicker and thicker to make advancing more difficult, this method is more often used, but labor-intensive.

Method 3: The use of high-pressure pumps (pressure 10~20Mpa) spray high-pressure water for flushing, the effect is better, mainly used for cleaning between the tube.

Method 4: The use of sponge ball on the heat exchanger tube for automatic cleaning. According to different layers of scale with different hardness of the sponge ball, for special hard scale, can be used with a “band” of emery sponge ball. Its role is to use the softer and elastic sponge ball into the heat exchanger tube, sponge ball compression and tube walls are in contact with the ball and the tube wall to produce relative motion, constantly friction tube wall, will be removed from the deposits.

Method 5: Often replace the cooling water, because the water use will produce scale, grease scale, rust scale, which is also a reason for the clogging of the copper pipe. Remove the front and rear cover, use the air gun to blow every hole in the copper pipe, blow out the scale, and then install the front and rear cover, 0 ring if there is damage replacement.

Maintenance of tube coolers

● Most cooler failures are caused by cooler tubes.

● Due to corrosion, vapor erosion, wear and tear of the tube wall thinning and perforation, but also due to thermal expansion and contraction, vibration generated by the fluid movement caused by the joints and other damages. After the cooler tube is broken, the two media will seep into each other and should be repaired in time, there are the following methods for reference:

Method 1: Find out the broken cooler tube, with the tube plug to plug both ends. Taper of the pipe plug between 3 to 5 degrees, the hardness of the pipe plug material should be lower than or equal to the hardness of the tube, the total number of plugged tubes shall not exceed 10% of the total number.

Method 2: Remove the broken tube and replace it with a new one for reexpansion.

Method 3: Leakage at the connection between tube end and tube plate should be reexpanded. If corrosion is severe, the tube bundle should be replaced.

GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8