Installation environment

The oil cooler should be installed in a well-ventilated area where the air is clean. The surrounding environment should be free from corrosive gases and hazardous materials that are flammable or explosive. Additionally, there should be no high-temperature heat sources or other heat-emitting objects near the installation location. Direct sunlight should also be avoided, especially on the electrical box of the machine. If the oil cooler is to be installed outdoors, appropriate rainproof measures should be taken, mainly to protect the electrical box and the control panel from rain.

Installation basics

The structural foundation on which the oil cooler is installed should be able to fully support the total weight of the machine. The foundation's level incline should not exceed 5 degrees.

Warning: It is strictly forbidden to install the oil cooler on a foundation that is subject to vibration or swaying. Otherwise, it may lead to the cracking of the internal pipelines in the oil cooler.

Installation principles

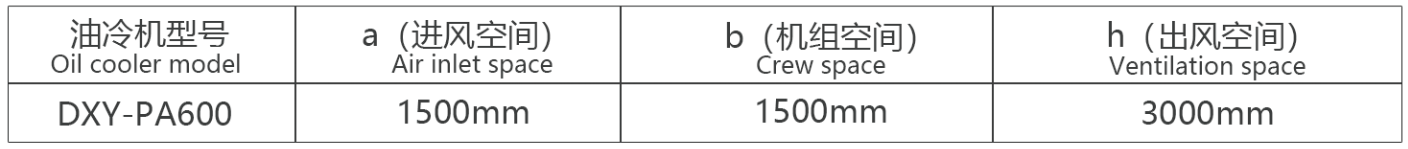

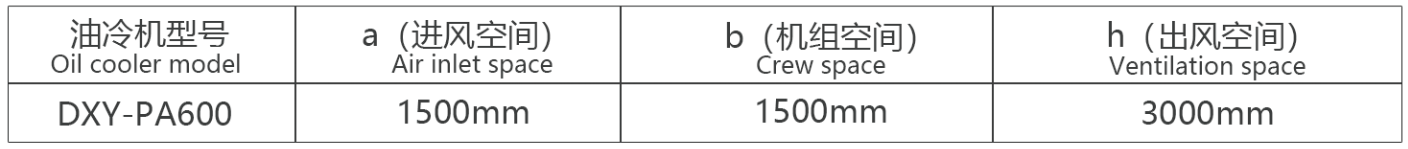

When installing the oil cooler, please refer to the diagram for the minimum space requirements around it and reserve

space according to the requirements in the table below.

Note:

a. It is strictly forbidden to install the oil cooler in an enclosed space with insufficient ventilation (less than the exhaust volume of the oil cooler).

b. Do not install ducting at the air outlet of the oil cooler's fan; otherwise, it will affect the normal heat dissipation of the oil cooler, leading to improper functioning or even damage to components.

c. If the space for installing the oil cooler is not reserved as required, it may lead to the unit not functioning properly or being difficult to maintain.

d. The control panel on the oil cooler contains electrical components, so it should be kept as far away from heat sources as possible and waterproofing measures should be taken.

Basic installation steps

After the oil cooler is in place, the oil circuit and electrical system should be connected in sequence.

Basic installation steps

After the oil cooler is in place, the oil circuit and electrical system should be connected in sequence.

Oil connection

The inlet/outlet oil interfaces of the oil cooler are all internal thread pipes, and larger diameters are flange interfaces (except for those with special interface requirements). When connecting the pipelines, it is essential to meet the specifications of the interface. Regardless of the type of interface, a flexible connector must be used between the pipeline and the interface.

GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8