Aluminum Alloy Bell Shape Cover Selection Description

1、Used to connect IEC standard motor and hydraulic oil pumps

2、The bottom of bell shaped cover is not solid but has reinforcement.

3、There are ventilation holes on the side, which is convenient to observe the operation of the machine.

4、Can be used for heavy load

5、Available for vertical and horizontal motors.

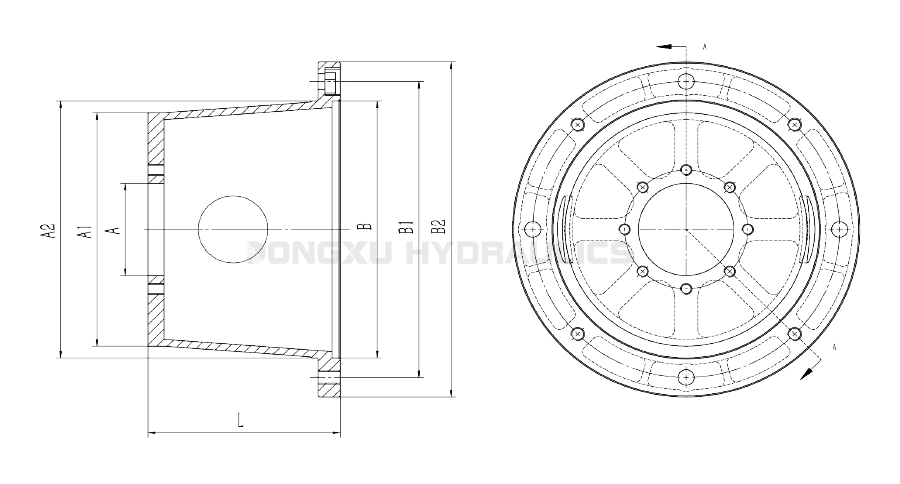

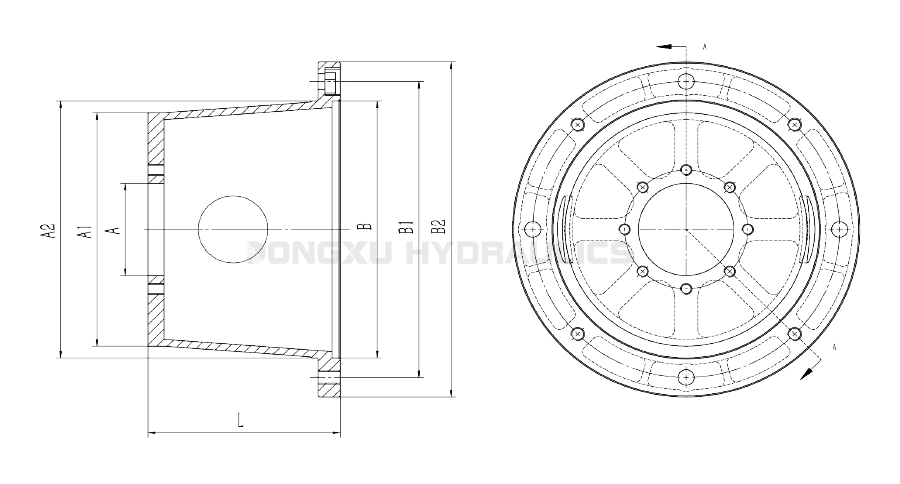

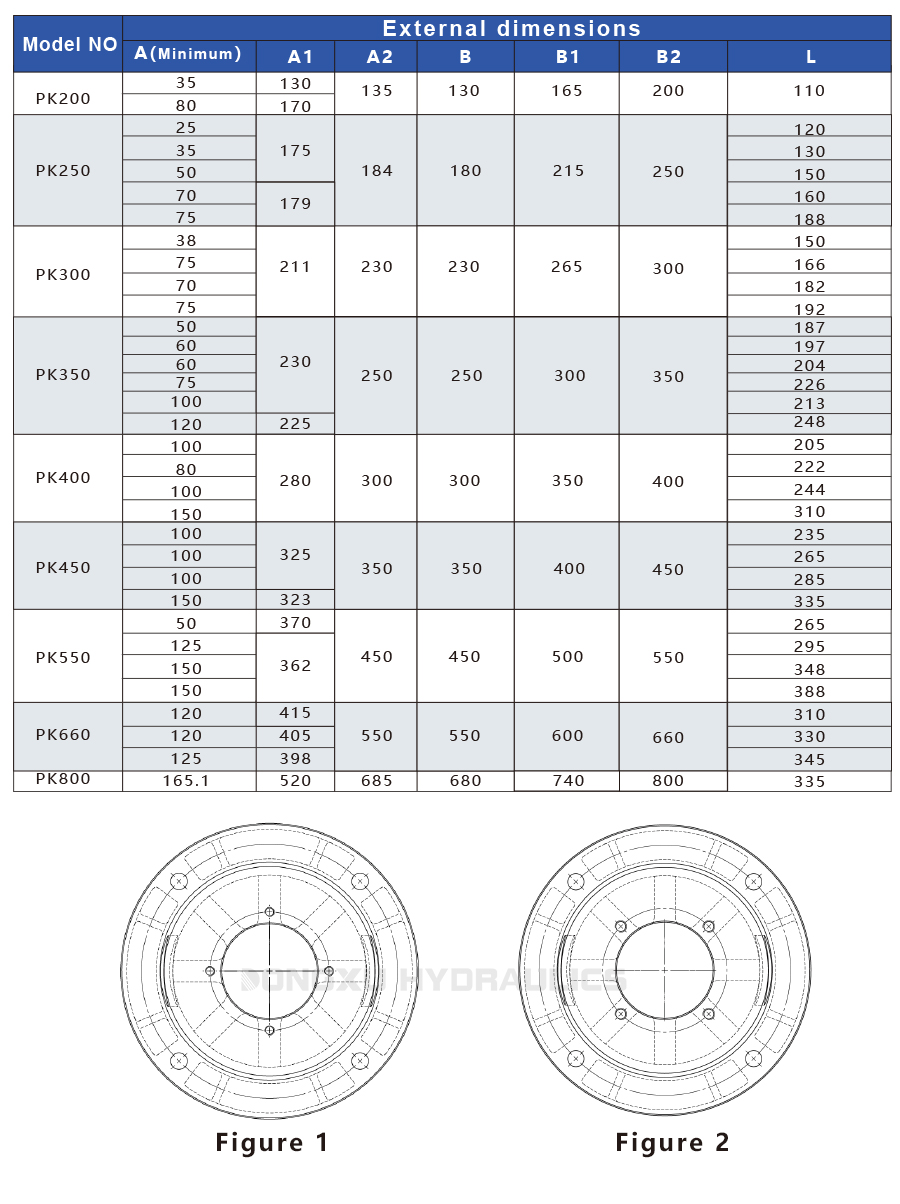

Bell Shape Cover Drawing

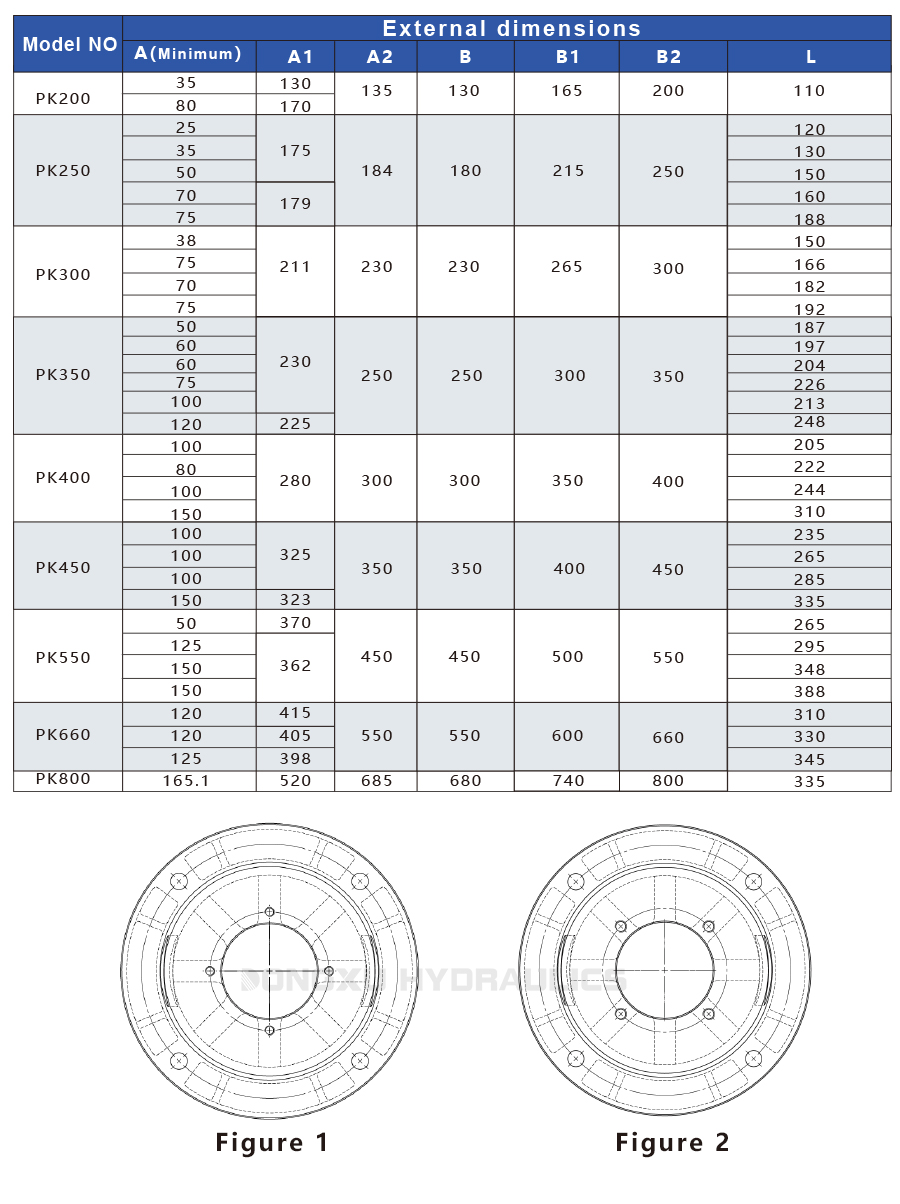

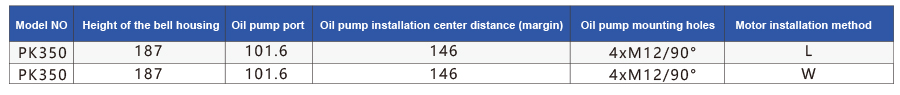

Bell-shaped cover model parameters

Description of bell jar selection (example)

L designation: 4 through holes and 4 threaded holes for vertical motor mounting.

W indicates: 4 through holes on the motor side for horizontal mounting.

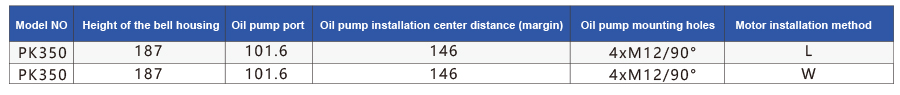

90° indicates: oil pump mounting (see schematic 1)

45° indicates: oil pump mounting (see diagram 2)

Remarks: The model and parameter of the oil pump will be provided by the customer and confirmed by the supplier's drawing.

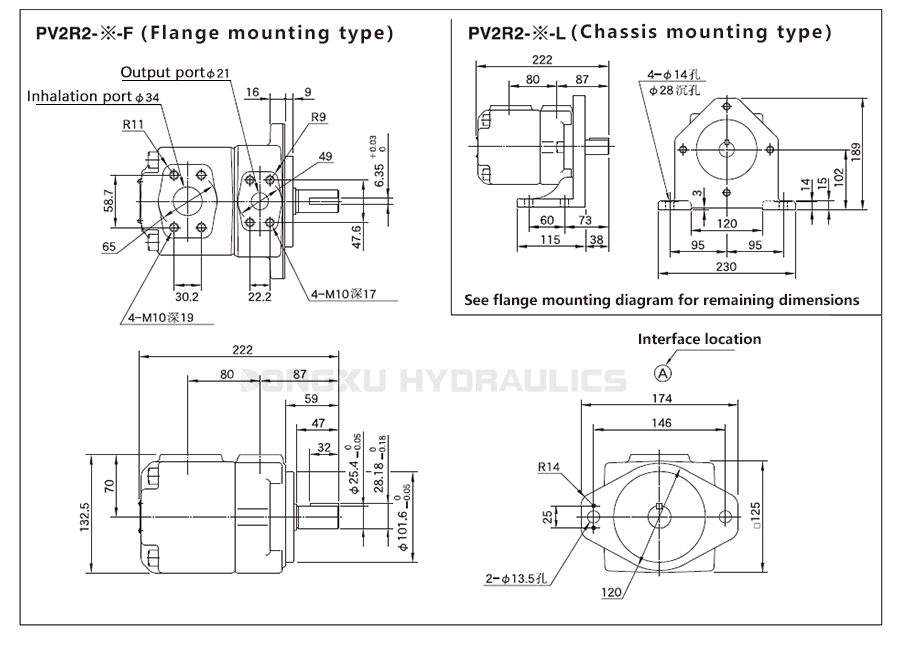

Please provide pump parameters before selection (example)

GR Flexible Coupling Selection Description

Product structure: It consists of two metal claw bushings on the left and right and a polyurethane star elastomer in the center.

Material of metal claw bushings: 45 steel.

Material of star elastomer: special polyurethane (hardness 98SHA, purple color).

This is a torsionally flexible coupling with fail-safe function. Its compact dimensions, low weight and low moment of inertia also allow the transmission of high torques. The high running quality and operating life of the coupling are due to the fact that all surfaces are finished. The star-shaped elastomer made of special polyurethane can effectively dampen the vibration generated by the coupling during operation, thus absorbing the shocks accompanying the uneven operation of the power and equipment ends. The deviation of the shaft during installation can be avoided due to the elastomer's drum-type gearing design, which prevents the concentration of stress and ultimately corrects the axial, radial, and angular mounting deviation effectively.

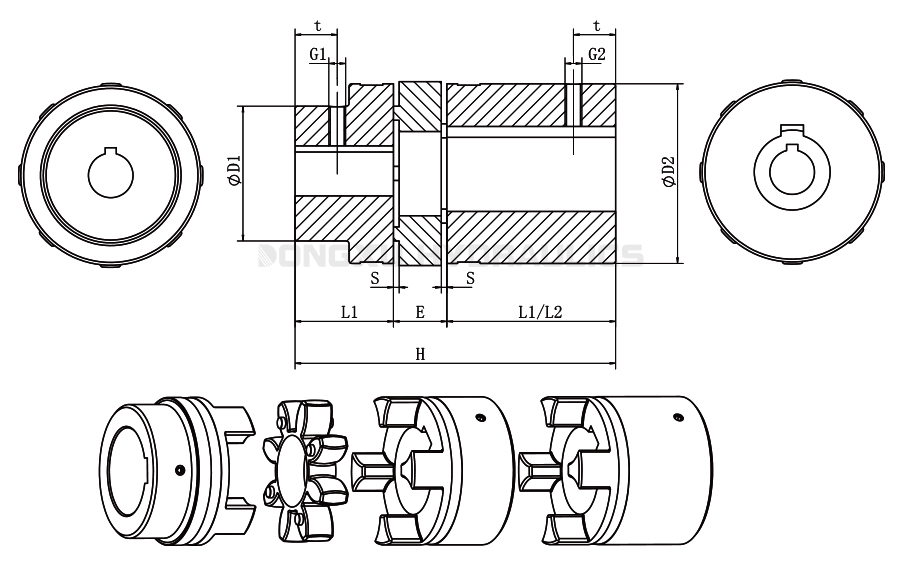

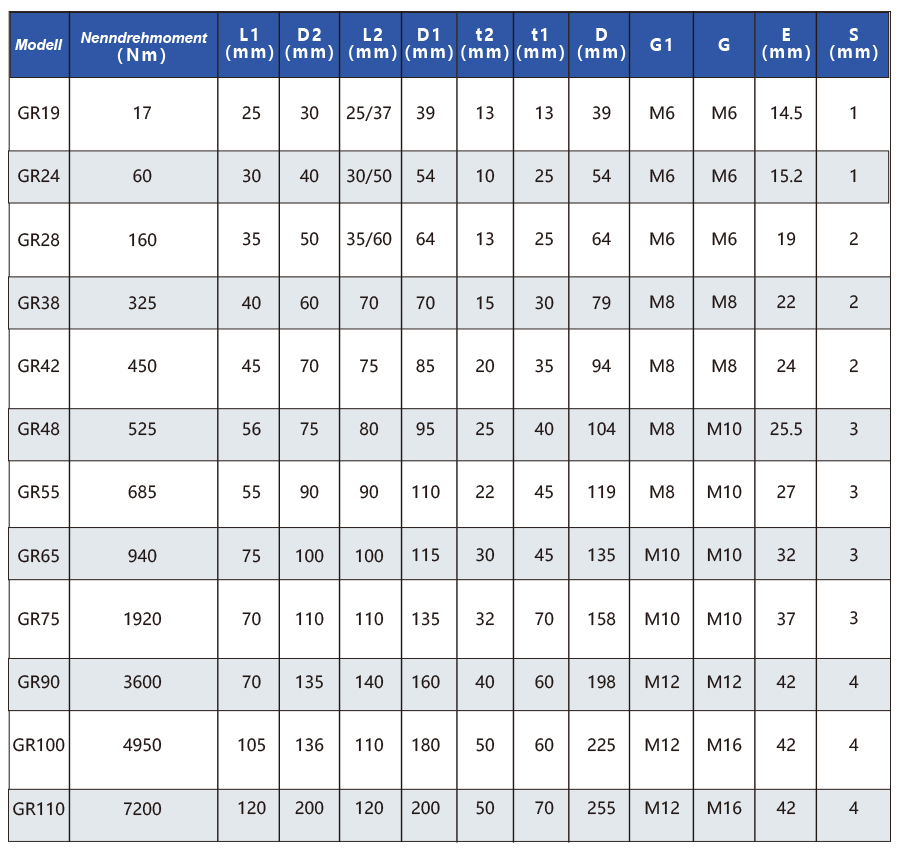

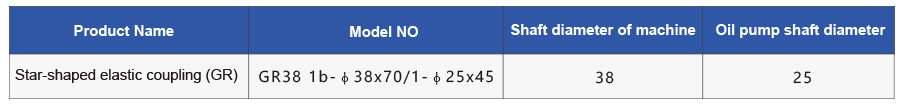

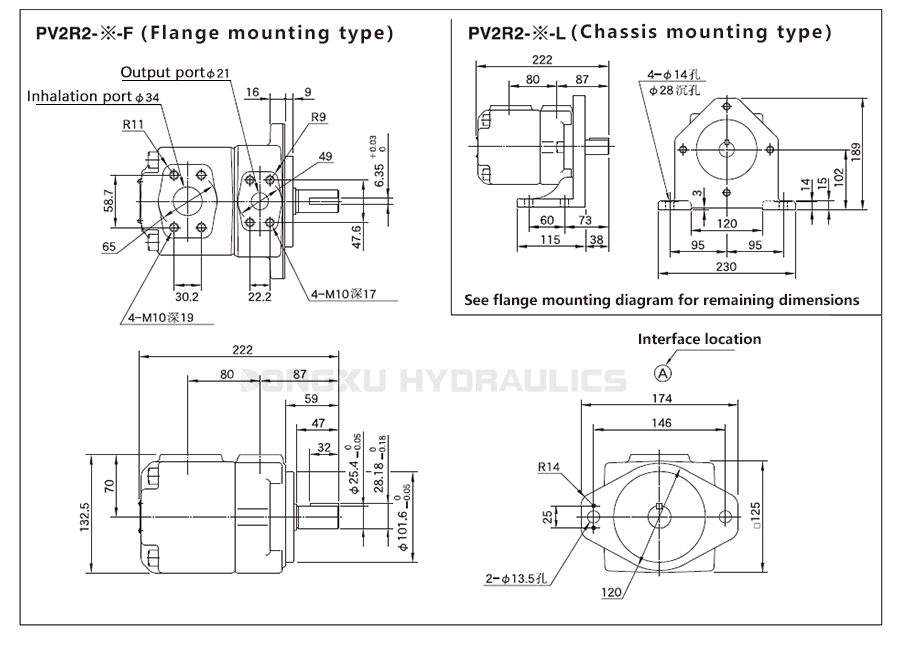

Coupling Drawings

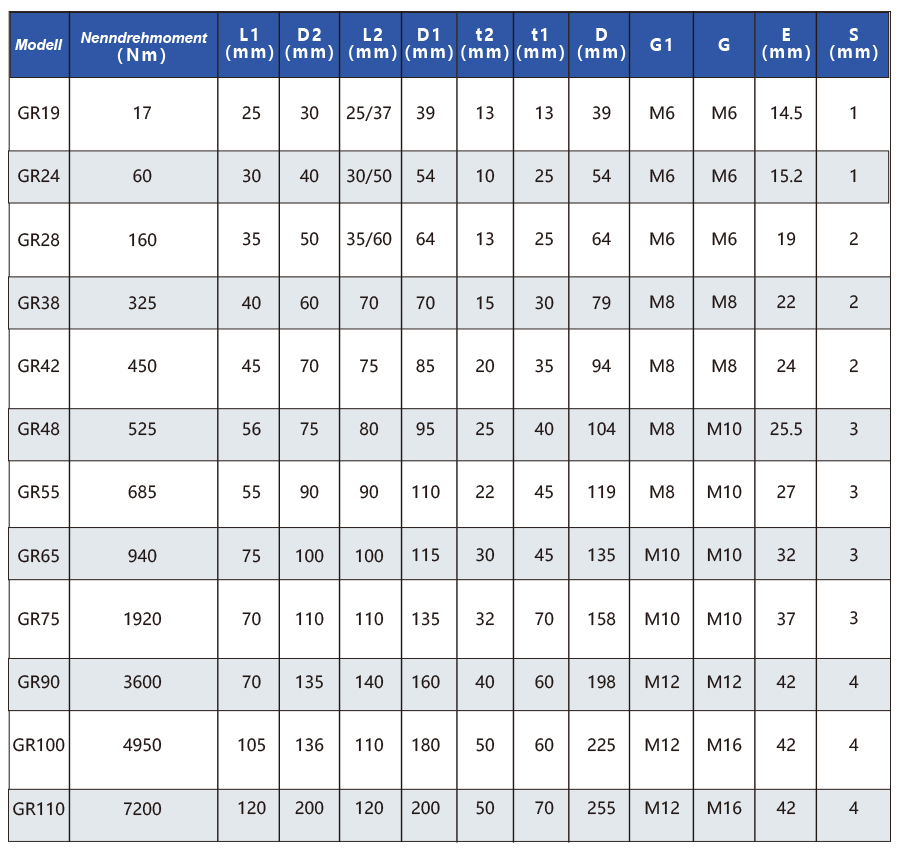

Coupling model parameters

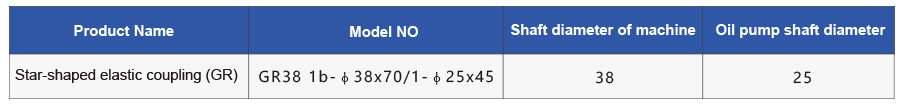

Description of coupling selection (example)

GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8 GearboxesAgriculture/Products8

GearboxesAgriculture/Products8